Transus Instruments / Products

Diagnostic software

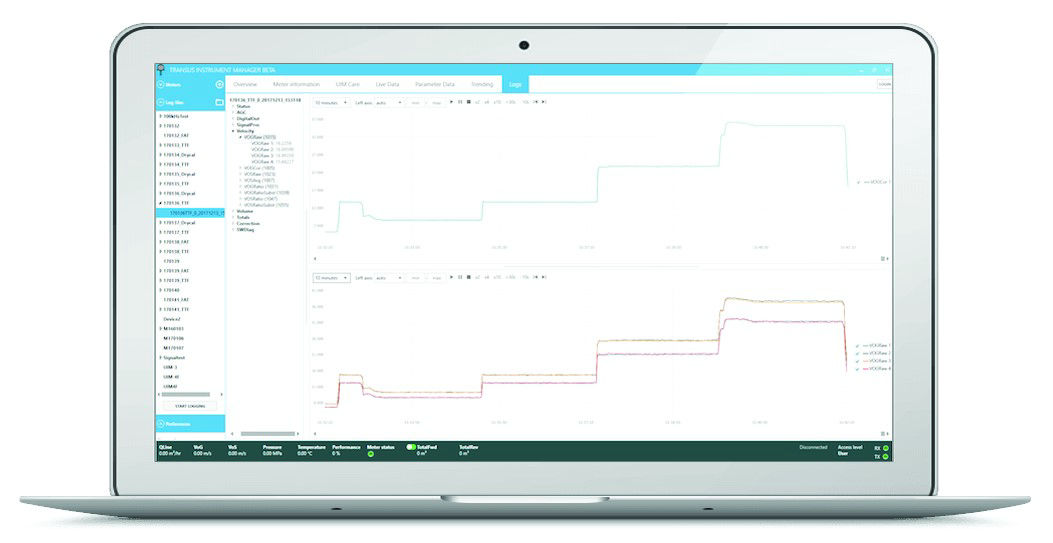

The UIM Series flowmeters provide extensive diagnostic information both on the graphic display screen and remotely via the Transus Instrument Manager TIMCare™ PC interface. Flow information and diagnostics may be logged over time to show trending and enabling real time condition monitoring.